AXIS#.PL.KFB.PIN

Description

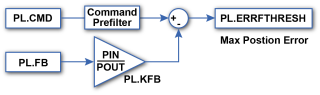

AXIS#.PL.KFB.PIN and AXIS#.PL.KFB.POUT allow the user to scale the position feedback source into the position control loops.

It is recommended to use AXIS#.PL.KFB.PIN and AXIS#.PL.KFB.POUT instead of AXIS#.PL.KFB due to possible precision loss, however it is not required. For example, the gear ratio 1:3 is precisely represented with the fraction 1/3 but lacks precision as a floating-point number 0.333333.

AXIS#.PL.KFB is related to AXIS#.PL.KFB.PIN/POUT in the following way:

AXIS#.PL.KFB = AXIS#.PL.PIN / AXIS#.PL.POUT.

This gain is especially useful in dual-loop applications where the position loop feedback and velocity loop feedback come from different devices. AXIS#.PL.KFB and AXIS#.VL.KFB can be used to synchronize the values.

Examples

Usage

Do not change from default (1) unless the application is using multiple feedback devices for an axis.

If the situation arose where two feedbacks were mounted to a rotary motor, and one of them was half the resolution of the first - and it was connected to the position feedback, while the full resolution device was connected to the velocity feedback, AXIS#.PL.KFB.PIN would need to be set to 2 and AXIS#.VL.KFB would be left at 1.0

Versions

| Action | Version | Notes |

|---|---|---|

| Implemented | 02-08-01-000 |

General Information

| Type | Read/Write |

| Units | N/A |

| Range | -2,147,483,648 to 2,147,483,647 |

| Default Value | 1 |

| Data Type | Integer |

| See Also | AXIS#.PL.KFB, AXIS#.PL.KFB.POUT, AXIS#.VL.KFB |

| Stored in Non Volatile Memory | Yes |

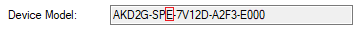

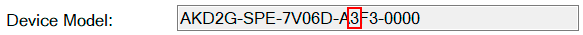

Variants Supported

All variants are supported.

Fieldbus Information

|

Command |

Index |

SubIndex |

Data Type |

Units |

Float Scale |

Access |

PDO Mappable |

|---|---|---|---|---|---|---|---|

|

AXIS1.PL.KFB.PIN |

500ch |

11h |

Signed32 |

- |

- |

Read/Write |

No |

|

AXIS2.PL.KFB.PIN |

510ch |

11h |

Signed32 |

- |

- |

Read/Write |

No |